Heat exchanger

The heat exchanger from AEL are the main components of many process plants. They transfer thermal energy between separate fluids. This may entail liquids and / or gases.

The heat exchanger can be used for all four important thermal engineering applications: Cooling, Heating, Condensation and Vaporisation.

No process and no plant resembles the other one. Therefore, we develop and produce customer-specific heat exchanger in the following models:

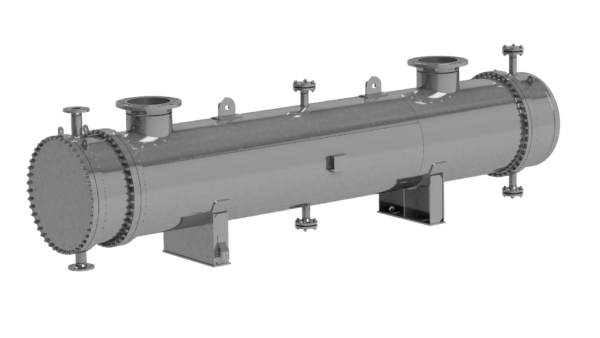

Shell and Tube Heat Exchanger

Principle of the enclosed tube bundle: Shell and tube heat exchanger consist of a hollow cylinder (shell) with inserted bundle of a large number of tubes. A medium flows through each of them. The tube bundles can be designed as straight- or U-tube and can be connected to the shell tightly or drawable.

Possible dimensions

| Shell diameter | 80 mm – 3,500 mm |

| Bundle length | 300 mm – 12,000 mm |

| Weight | ≤ 125 t |

Upon request, it is also possible to deliver products outside of this dimensioning range.

Production of all recognised types

The nomenclature of the TEMA (Tubular Heat Exchanger Manufacturing Association, USA) is the internationally recognised standard for types of shell and tube heat exchanger. Many applications can be realised on this basis. AEL develops and produces shell and tube heat exchanger of all TEMA types. Furthermore, we also produce according to other standards (e.g. Working Group for Pressure Vessels, ASME, GOST, British Standard).

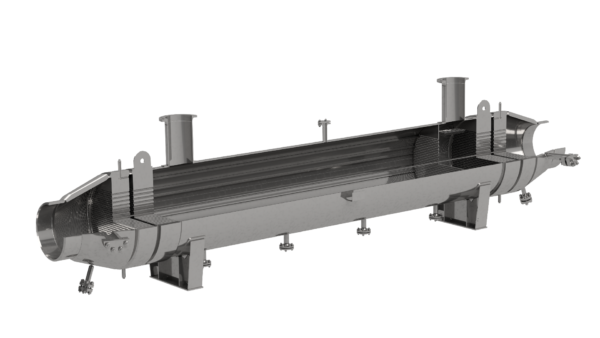

Plate-Fin Heat Exchanger

A special design of the shell and tube heat exchanger – an element cooler with rectangular tube bundle and plate fin. Due to the large surface, heat exchanger of this kind have a high performance with comparatively low pressure losses.

Double Tube Heat Exchanger

Double tube instead of shell: Double tube heat exchanger do not consist of tube bundle and shell, but only of a tube bundle – with outer and inner tube. In this way, it is possible to create pure counter current, which provides a particularly intensive heat transfer. Therefore, double tube heat exchanger are particularly used for smaller throughput quantities and lower temperature differences. Generally, they need a lot of room because several double tube segments are compiled in a register.

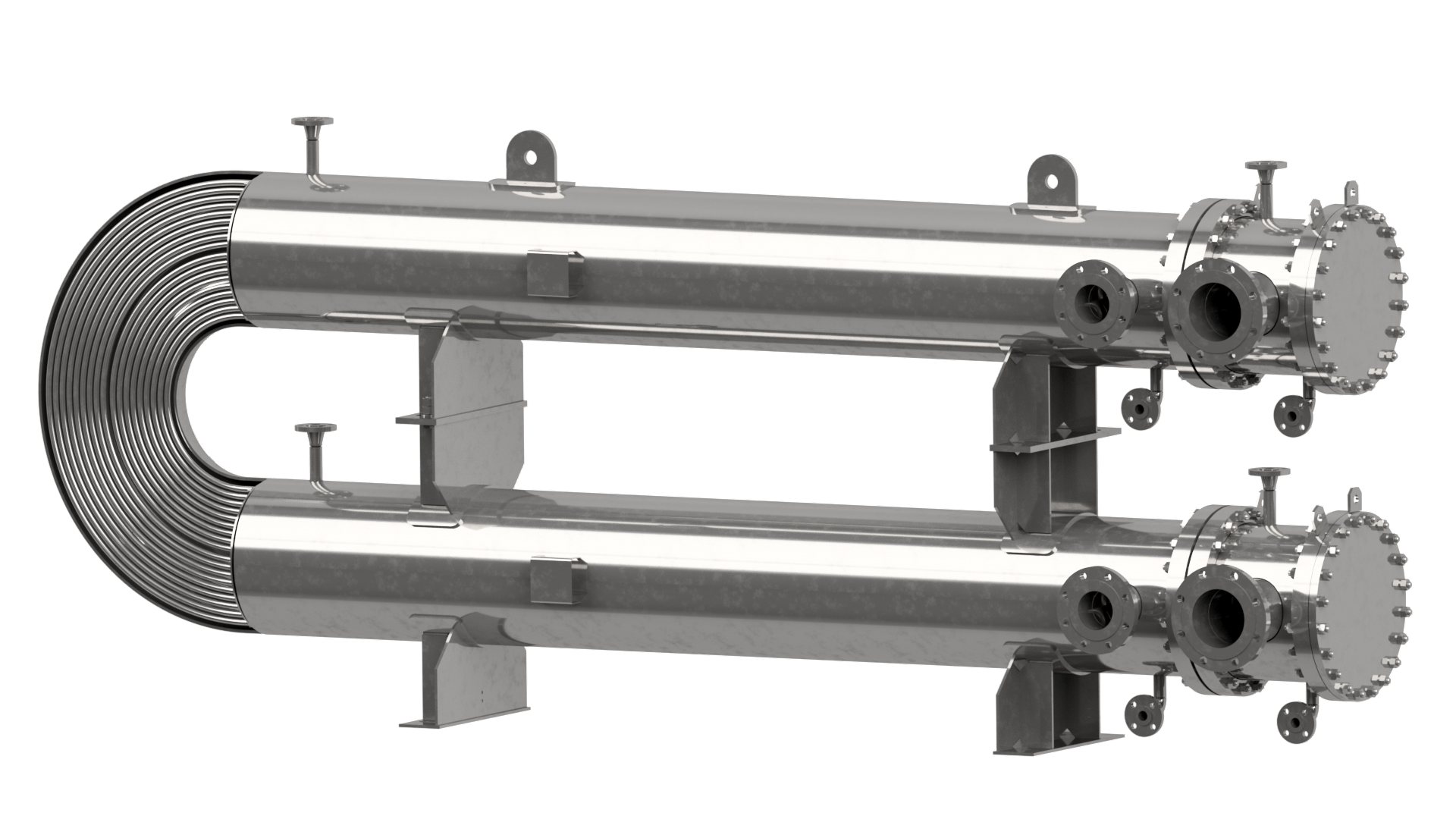

Hairpin Heat Exchanger

Shell and tube heat exchanger with U-tube bundle the legs of which are all sheathed: The shell tube system as a whole is bend back by 180° in case of this type, which shapes the heat exchanger as a hairpin. Such solutions are space-saving and are also suitable for media with large temperature differences due to their low thermal expansion. Hairpin heat exchanger are used, for example, for waste heat utilisation, exhaust gas treatment, evaporation and condensation.

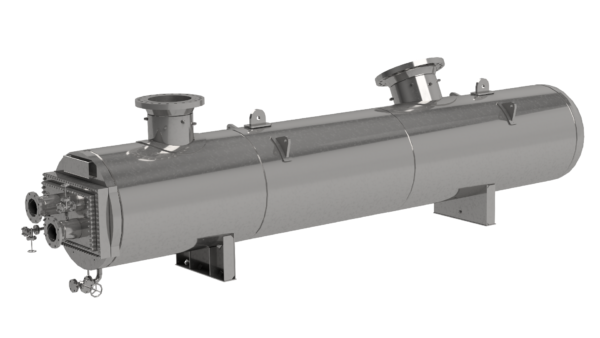

Double Tube Safety Heat Exchanger (SiRo)

With safety double tube: SiRo heat exchanger are a special design of shell and tube heat exchanger for the handling of hazardous media. The double tube wall prevents the contact with media even in case of leakages. Additionally, designs with double bottoms are available. SiRo designs are used, for example, in the chemical, pharmaceutical and food industry. They are also often requested for oil cooling systems in mechanical and plant engineering for environmental reasons.

Materials used for heat exchanger

| Shell | • Carbon steels • Low-alloy steels • High-alloy steels • Heat resistant steels |

| Tubes | • Carbon steels • Low-alloy steels • High-alloy steels • Heat resistant steels • Copper • Cu-Ni-alloys • Brass • Titanium • Ni-base alloy |